Phone:0086-185-39931566

- Home

- Product

- Oil Pressing Machine

- Small Capacity Hot Sale Peanut Roaster Machine

- Commercial Gas Peanut Drum Roasting Machine

- Automatic Oil Press Machine For Sale

- Hot Sale Peanut Drum Roaster Machine

- Automatic Oil Press Machine for Avocado Oil/Hemp Seed Oil

- GGJG-400 Peanut Dryer and Roaster Machine for Spices

- Hydraulic Sesame Seed Oil Extracting Machine|Almond Oil Cold

- Huller Machine

- Automatic Pine Nuts Buckwheat Hulling and Separating Machine

- Hot Sale Almond Skin Removing Peeling Machine With Factory Pr

- Buckwheat Hulling Machine|Buckwheat Sheller Price

- Automatic Pumpkin Seed Shelling Machine

- New Industrial Pumpkin Seeds Sheller Shelling Machine

- Automatic Almond Cracking Shelling Machine

- Wet Peanut Red Skin Peeling Machine Suppliers

- Roasted Peanut Skin Peeling Machine For Sale

- Dry Type Peanut Peeler Machine For Sale

- Rice Huller for Hemp Seeds|Buckwheat

- Grain Washer and Dryer

- Professional Sesame/Wheat Washing and Drying Machine

- Sesame Washing and Drying Machine

- Rice Washing Machine

- Rice Dryer Machine

- Beans Washing Machine

- 2015 New Stainless Steel Rice Washing Machine

- Promotional Stainless steel Peanut washing machine

- Hot sale Promotional Stainless steel High quality Peanut clea

- Grain Dryer Machine

- Hot Sale Rice Drying Machine

- Toothpick Making Machine

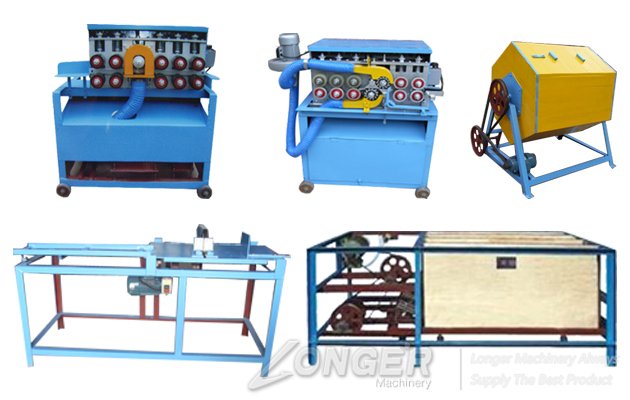

- Bamboo Toothpick Processing Line|Toothpick Production Line

- Manual Wood Stick End Rounding Machine

- Wooden Round Ice Cream Stick Making Machine Product Line

- Bamboo Toothpick Processing Machine

- Round Wood Stick Making Machine

- Wood BBQ Stick Making Machine Line

- Wooden Toothpick Product Line|Wooden Tooth Pick Making Machin

- Round Disposable Wooden Chopsticks Making Line

- Circular Rod Tooth-discharging and cutting and rounding machi

- Manual Model Wood Stick Threading Machine

- Tongue Depressor Machine

- Automatic Wood Ice Cream Stick Product Line For Sale

- Automatic Wood Log Rotary Cutting Machine for Sale

- Automatic Wood Ice Cream Stick Product Line

- Automatic Wood Ice Cream Stick Bundling Machine

- Industrial Automatic Ice Cream Stick Product Line

- High Quality Automatic Wood Ice Cream Stick Making Machine

- Automatic Wood Ice Cream Stick Bundling Machine for Sale

- Automatic Ice Cream Stick Drying Machine

- Commercial Automatic Ice Cream Stick Branding Machine

- Automatic Wood Ice Cream Stick Making Machine

- Wooden Crushing Machine

- Grain Crushing Machine

- Stainless Steel Spices Powder Grinder|Sugar Grinding Machine

- 2015 Best Wood Shaving Machine for Poultry Bedding

- New Design High Output Wood Shaving Machine Price

- 50-40 Big Hopper Straw Hammer Mill

- Straw Hammer Mill,Straw Cutter

- LG50-40 Straw Hammer Mill

- Straw Crushing Machine

- Hammer Mill Crusher

- 36New Straw Hammer Mill

- Grain Milling Machine

- Household Flour Mill/Hammer Mill LG-23A Model

- Household Flour Mill/Hammer Mill LG-15 Model

- Household Flour Mill/Hammer Mill LG-19 Model

- Best price Home Use Rice Mill Machine

- Stainless Steel Grinding Machine

- Professional Peanut Mill Machine for Sale

- Almond Crusher/Nut Crusher

- Household Flour Mill/Hammer Mill LG-21 Model

- Household Flour Mill/Hammer Mill LG-23 Model

- Household Flour Mill/Hammer Mill LG-29 Model

- Packing Machine

- Automatic Bag-sewing machine

- Automatic Turnplate Packing Machine LG-480

- Chain Bucket Automatic Packing Machine LG-350

- Feed Pellet Weighting and Packing Machine LG-480

- Particles Quantitative Packing Machine

- Wood Pellet Packing Machine LG-350

- Chain Bucket Automatic Packing Machine LG-320

- Feed Pellet Weighting and Packing Machine

- Semi-automatic Racking Machine

- Planter and Harvester Machine

- New Digital Seed Counting Machine

- Garlic Heavesting Machine for Sale

- Hot Sale Multifunctional Oat Peeling Machine With Low Price

- Fresh Corn Thresher

- mini corn thresher with electric power

- High quality Promotional Peanut picker

- Multi-function Potato Fertilizing/Harvesting Machine

- Agericulture Machinery Vegetable Precise Sower

- Wheat Fertilizing and Sowing Machine/Wheat Seeder

- Cotton Stalk Puller for Sale

- Charcoal Machine

- Agriculture Use Garlic Harvester Machine|China Made Garlic Ha

- Air Current Type Sawdust Dryer

- Chicken Pellet Making Machine For Sale

- Portable Cotton Picking Machine, Long Time Working Cotton Pic

- LONGER LG-560 High Capacity Wood Pellet Mill|Straw Dust Mill

- Sawdust Briqueting Machine LGZB-1

- Wheat Sowing Machine|Wheat Fertilizing and Sowing Machine

- Different Capacity LG Series Pellet Mill

- LG-4035 small model heat shrink packaging machine

- Hot sale Charcoal Production line

- Oil Pressing Machine

- Service

- News

- About Us

- Case

- Contact Us